Metal fabrication welding is an integral part of the entire fabrication of the metal process. It helps in providing services to an impressive array of processing technologies. Apart from welding, some of the other services the metal fabrication industry can offer are CNC punching, laser, CNC forming, rolling, and hardware additions. Apart from these, for offering the best final additions, a Metal Fabrication Welding firm should also manage other facilities like painting, plating, and so on.

Among the different metals and metal alloys that require fabrication welding firms for various welding, forms are stainless steel, carbon steels, and aluminum. The various technologies, which any quality firm brings to the table, include MIG, TIG, MMA, and Brazing. Some of the metal fabrication welding projects include stands and tables for TVs/LCD TVs, stands for tabletop machinery, food packaging machines, etc. The various fabrications need in the hotel equipment category include trolleys, working cabinets and shelving, and various high-precision metal components, etc.

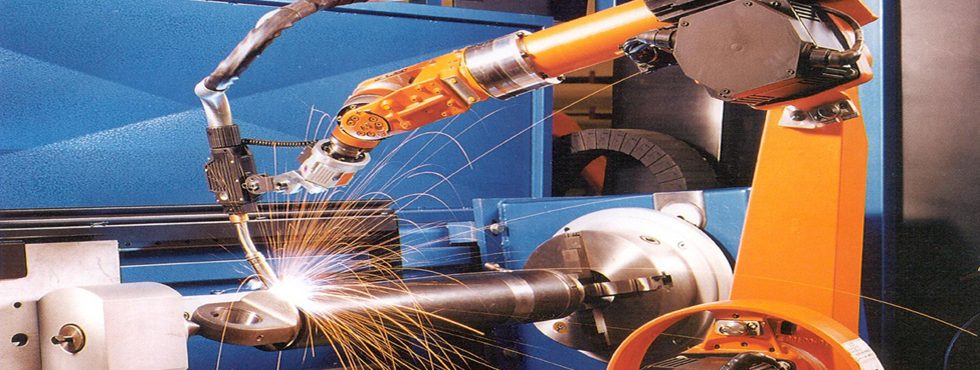

Drive production efficiencies with advanced technologies is the basis of welding in the fabrication process today. One of the most used techniques in this process is the arc welding method. It is nothing but the use of an electric arc created between an electrode and the base material used to melt the metals at the welding point. The current can be either direct (DC) or alternating (AC) current, and the electrodes can be consumable or non-consumable. A quality team can offer both conventional and hybrid arc systems and is highly skilled in the entire arc welding, surfacing, and cutting technologies.

Among the various industries that use fabrication welding processes are the construction, consumer goods, defense, energy, and transportation industries. In the construction segment, this is used in heavy construction and repair equipment, mining and off-highway vehicles, etc. In consumer goods, you would find this used among medical manufacturers for developing smaller, lighter, safer medical devices that meet industry demand for higher product quality, reduced cost, and greater production efficiencies. Again, in packaging manufacturing, they are used to produce polymers, plastics, and adhesives.